My DA Microfiber System Review...

First off, I'd like to say a HUGE thank you to Jason Rose and Kevin Brown! Without these two guys extreme passion, we wouldn't have these products! I was first introduced to this system back about 3.5-4 years ago, and Kevin and Jason had been working on this long before then. I honestly don't have a clue how long this has been in development, but I'd personally like to thank you guys for your passion and stubbornness for this products excellent performance capabilities! You guys knocked it out of the park on this one! Quite possibly, the single best detailing product I've seen since the DA polisher was introduced into the detailing world, or the foam pad, or clay!! Yes I am that fond of this system!

I'm not gonna bore you guys with "priming pictures" or base pictures of the pads and products themselves, this has been covered quite a bit by the other users, and I think they did an excellent job providing you with that information, along with their opinions of the system itself, and it's performance for them.

Onto the show...

Honestly, my first impression of these pads were horrible! I actually hated them! For me, the learning curve was huge, and I guess I was a bit on the stubborn side about them. I mean, how could something as simple as a microfiber product on a DA Polisher be better than a rotary, right? I mean think about it! We're talking about a high speed rotary buffer vs a wimpy DA Polisher(G100 when I was first introduced to this product)! How could the DA Polisher even compare? Boy was I wrong! LOL! My first learning curve was "slower is better". This was probably the single biggest thing for me to get over, and I still have issues with it today. If a little is good, then more must be better! Wrong! Since then, I've completely put down my rotary buffers. Yes, thats right, I haven't used a rotary buffer in a very long time! For 99% of the cars I've worked on, this system has worked flawlessly! There was one car, it had an aftermarket paint job on it, and as tough as nails!

In my experience with this system, I have used the Meguiar's G100, Meguiar's G110v2, Griots DA Polisher, Flex DA and the Metabo(for 3"), as my electric machines. I've also used air, but have only had decent success with cutting, and great success with polishing. I don't have access to a tool to read OPM's, so this is uneducated advice at best

My speed settings for each machine:

G100- 4.5-5.0

G110- 3.5-4.5

Griots 3.0.4.0

Flex DA 3.0-4.0

Metabo 4.0-5.0

Please keep in mind that this is my personal preference. What I've noticed from these speeds is an awesome cutting machine, and it finishes out incredible! And this speed setting is with ALL products....DA Compound, Polish Wax, M105, M205, etc... For me, these seem to be the "magic numbers" for the DA Polisher settings. For you "car guys" out there, think of it like this, this system doesn't like a lot of horsepower, but it absolutely LOVES the torque!

The Flex DA was a bit to "grabby" for me cutting, but it does work. I prefer the DA over the Flex DA for cutting. I have more control with the DA Polisher, and it's just more comfortable for me. This doesn't mean the Flex DA doesn't work, it's just not my "choice" machine for this system when cutting. However, it is a great tool for the Finishing Wax to use after the DA Compound, or as a 1-Step procedure over a car.

Onto the pictures...

This is an absolutely tore up Ford F250. Has been used as a farm truck for the last few years, and it shows! I've completed at least a hundred vehicles with this system(mainly the pads), and this is by far the worst paint I've put it up against.

Before:

Tore up from the floor up! lol!

Taping it off to separate...

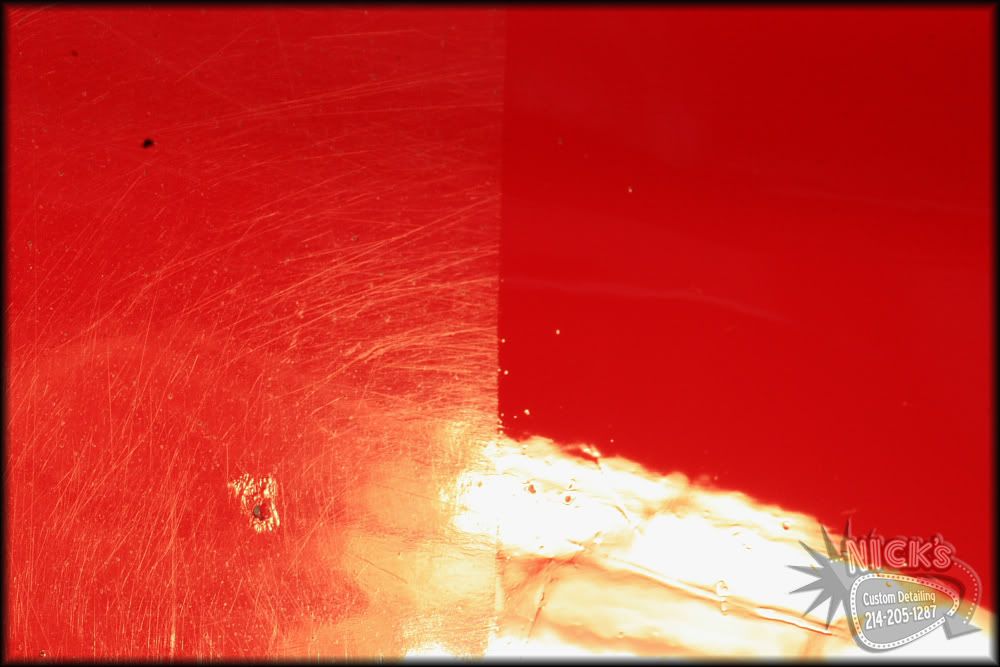

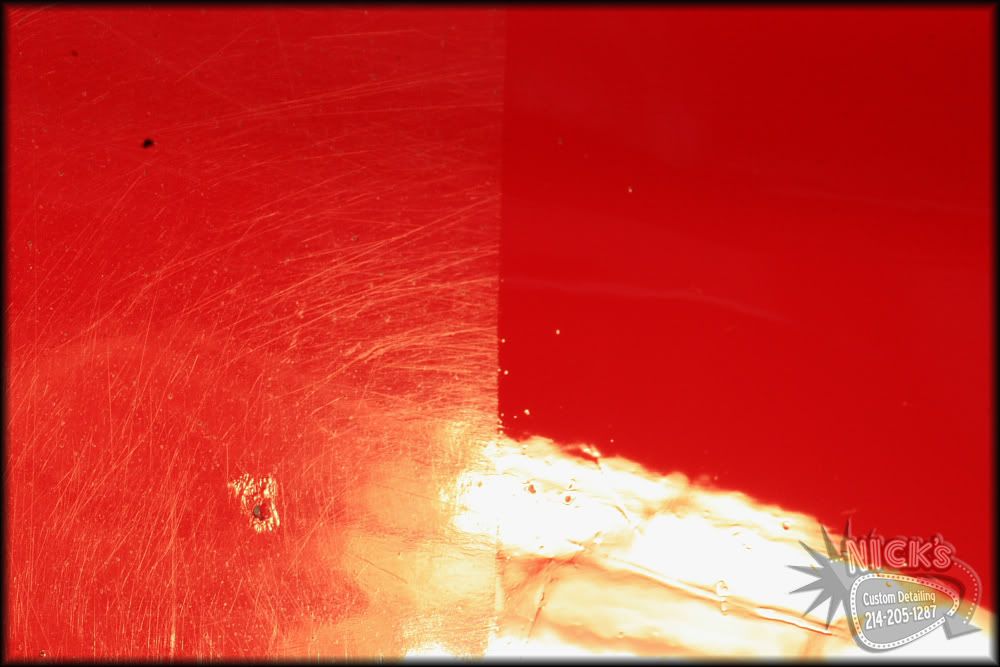

Here's the finished 50/50 shot...

And the side of the bed, same process...

And a really nice close up so you can really see the difference...

Please keep in mind that this was with two passes of the DA Compound, and nothing to finish after. This is LSP ready Did you hear me? LSP READY WITH A COMPOUND!!! LOL!!

Also, I saw a recent post from someone to stay away from vinyl. Now this has been pretty true for most applications of most previous methods or systems, but with this picture below, can you really say that this system doesn't work on vinyl? If I would have known this was an issue, I would have taken better pictures, but I think you can see how well the vinyl looks in this picture.

Now I have 4 rotary buffers, and a minimum of 500+ foam pads that are just sitting around, doing nothing but collecting dust! I see a very large online garage sale in my future! Just don't tell anyone about this system so I won't have a problem selling all these pads, deal? Thanks!

I have a TON more pictures, just not sure if we're able to post them all in the other "before/After" forums yet.

Hope this helps you understand this system a bit more from "another prospective".

If you have any questions, please feel free to ask!

Nick

First off, I'd like to say a HUGE thank you to Jason Rose and Kevin Brown! Without these two guys extreme passion, we wouldn't have these products! I was first introduced to this system back about 3.5-4 years ago, and Kevin and Jason had been working on this long before then. I honestly don't have a clue how long this has been in development, but I'd personally like to thank you guys for your passion and stubbornness for this products excellent performance capabilities! You guys knocked it out of the park on this one! Quite possibly, the single best detailing product I've seen since the DA polisher was introduced into the detailing world, or the foam pad, or clay!! Yes I am that fond of this system!

I'm not gonna bore you guys with "priming pictures" or base pictures of the pads and products themselves, this has been covered quite a bit by the other users, and I think they did an excellent job providing you with that information, along with their opinions of the system itself, and it's performance for them.

Onto the show...

Honestly, my first impression of these pads were horrible! I actually hated them! For me, the learning curve was huge, and I guess I was a bit on the stubborn side about them. I mean, how could something as simple as a microfiber product on a DA Polisher be better than a rotary, right? I mean think about it! We're talking about a high speed rotary buffer vs a wimpy DA Polisher(G100 when I was first introduced to this product)! How could the DA Polisher even compare? Boy was I wrong! LOL! My first learning curve was "slower is better". This was probably the single biggest thing for me to get over, and I still have issues with it today. If a little is good, then more must be better! Wrong! Since then, I've completely put down my rotary buffers. Yes, thats right, I haven't used a rotary buffer in a very long time! For 99% of the cars I've worked on, this system has worked flawlessly! There was one car, it had an aftermarket paint job on it, and as tough as nails!

In my experience with this system, I have used the Meguiar's G100, Meguiar's G110v2, Griots DA Polisher, Flex DA and the Metabo(for 3"), as my electric machines. I've also used air, but have only had decent success with cutting, and great success with polishing. I don't have access to a tool to read OPM's, so this is uneducated advice at best

My speed settings for each machine:

G100- 4.5-5.0

G110- 3.5-4.5

Griots 3.0.4.0

Flex DA 3.0-4.0

Metabo 4.0-5.0

Please keep in mind that this is my personal preference. What I've noticed from these speeds is an awesome cutting machine, and it finishes out incredible! And this speed setting is with ALL products....DA Compound, Polish Wax, M105, M205, etc... For me, these seem to be the "magic numbers" for the DA Polisher settings. For you "car guys" out there, think of it like this, this system doesn't like a lot of horsepower, but it absolutely LOVES the torque!

The Flex DA was a bit to "grabby" for me cutting, but it does work. I prefer the DA over the Flex DA for cutting. I have more control with the DA Polisher, and it's just more comfortable for me. This doesn't mean the Flex DA doesn't work, it's just not my "choice" machine for this system when cutting. However, it is a great tool for the Finishing Wax to use after the DA Compound, or as a 1-Step procedure over a car.

Onto the pictures...

This is an absolutely tore up Ford F250. Has been used as a farm truck for the last few years, and it shows! I've completed at least a hundred vehicles with this system(mainly the pads), and this is by far the worst paint I've put it up against.

Before:

Tore up from the floor up! lol!

Taping it off to separate...

Here's the finished 50/50 shot...

And the side of the bed, same process...

And a really nice close up so you can really see the difference...

Please keep in mind that this was with two passes of the DA Compound, and nothing to finish after. This is LSP ready Did you hear me? LSP READY WITH A COMPOUND!!! LOL!!

Also, I saw a recent post from someone to stay away from vinyl. Now this has been pretty true for most applications of most previous methods or systems, but with this picture below, can you really say that this system doesn't work on vinyl? If I would have known this was an issue, I would have taken better pictures, but I think you can see how well the vinyl looks in this picture.

Now I have 4 rotary buffers, and a minimum of 500+ foam pads that are just sitting around, doing nothing but collecting dust! I see a very large online garage sale in my future! Just don't tell anyone about this system so I won't have a problem selling all these pads, deal? Thanks!

I have a TON more pictures, just not sure if we're able to post them all in the other "before/After" forums yet.

Hope this helps you understand this system a bit more from "another prospective".

If you have any questions, please feel free to ask!

Nick

I can not wait to get my hands on this new M/F system.

I can not wait to get my hands on this new M/F system. I mean, now anyone has the potential to turn out top quality work, even the average do-it-yourselfer, in the garage at home. This system could be a curse for some of us instead of a blessing lol!

I mean, now anyone has the potential to turn out top quality work, even the average do-it-yourselfer, in the garage at home. This system could be a curse for some of us instead of a blessing lol!

Comment