I'm new to the world of machine use. Just ordered the G110. I've been reading about D.A.'s for couple months now. I'm just curious/confused about pads. I see that meg's, which is what I went with, has three pads: cutting, polishing, finishing. Seems simple enough. Then I see Griot's has only polishing and finishing. Then lake country, as an example has, if memory serves, about EIGHT different pads to choose from. As I stated, I bought meg's because it seemed less confusing. I bought one cutting pad, two each of the polishing and finishing. Seemed to me like this would get me started. So what is with the vast selection other companies have?

- If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below.

Announcement

Collapse

No announcement yet.

pad selection driving me crazy!!!

Collapse

X

-

Re: pad selection driving me crazy!!!

Some people seem to want to fine tune their pad selection for the various paint conditions and compounds they will use.What you have ordered in my opinion will be just fine to start out and as you learn the machine which you have selected.Both the machine and pads have a good reputation.Good luck and I think again you will be happy with your purchase.

..................... Paul S ................................Live like you're not afraid to die.Don't be scared, just enjoy your ride. Chris Ledoux RIP

PAUL SPARKS / Distinctive Auto Detailing

317-513-4678

-

Re: pad selection driving me crazy!!!

to keep it simply Meguiar's only has the Polishing and Finishing pads for DA which is more than enough... cutting pads are usually used for Rotary...

there are so many variables of pads some are more soft, some are more dense, it all depends on what you are used at using and what you feel more comfortable with.. and the only way to answer this is try it yourself.. but since your new to DA, i think a Meguiars Polishing and Finishing pad will give you great results..

Originally posted by Michael Stoops View Post

The list above is only a starting point. Ultimately which products you choose will be determined by your skill, the condition of the paint, how hard or "polishable" the paint is, and your personal preferences - especially with regard to your final wax selection.

Some other things to keep in mind when working with the G110/G220 dual action polisher:

1) Pressure – How much pressure you apply to the pad will increase the “cutting action” of the pad/liquid combination. In some cases this is needed, and in other case this could be detrimental to the surface. Generally speaking you will use more pressure when correcting defects and less when applying a wax.

2) OPM – By increasing the OPM (oscillations per minute) of the machine, you automatically increase the action of the machine. This means additional “cutting action” when using products that have defect removal capability. If you’re simply spreading a wax or pure polish, however, you should reduce the speed of the machine for this step.

3) Arm Speed – The quicker you move your arms back and forth, the less chance the product has to do it job. Slow down your arm speed to give the pad/liquid combination more time to concentrate the work over a given area. When applying a wax you can move the machine a bit more quickly, but still move the machine in purposeful movements to ensure a thorough and even application of the wax.

4) Work Area - Just as your arm speed determines how much time the pad/liquid combination can work a given area, so does the overall size of the area being worked. Shrink your work area down to no more than 2' x 2'. Don't try to work the entire hood of your vehicle at once; you'll be spreading the work over too large an area, run the risk of product drying out, and diminish the overall effectiveness of the product. The work area changes dramatically when applying wax as you can now cover all the painted surfaces at once.

5) Pad Choice – The more aggressive the pad, the more “cutting” action will take place. You must first evaluate your finish, determine your goal, and then choose the appropriate pad to do the job. Generally a W8207 Soft Buff 2.0 Polishing Pad will be used with a paint cleaner or cleaner/polish to remove defects. For applying a pure polish or wax you would select a W9207 Soft Buff 2.0 Finishing Pad.

6) Product Choice - The more severe the defect, the more aggressive the product needed to remove them. Heavy swirls in hard paint will be a big challenge for a mild cleaner/polish while a dedicated paint cleaner may make very short work of them. Determining which product is right for the job is best determined by doing a test spot first and evaluating the results. There is nothing more frustrating than just jumping in with a randomly selected product and working over the entire vehicle, only to find it wasn't effective at removing the defects. On the flip side, there is no reason to use an overly aggressive product in a situation where a mild approach would yield the same result.Ganesa,

Toyota Vios '05

Theres a difference in a person who has to do it and a person who wants to do it

Comment

-

Re: pad selection driving me crazy!!!

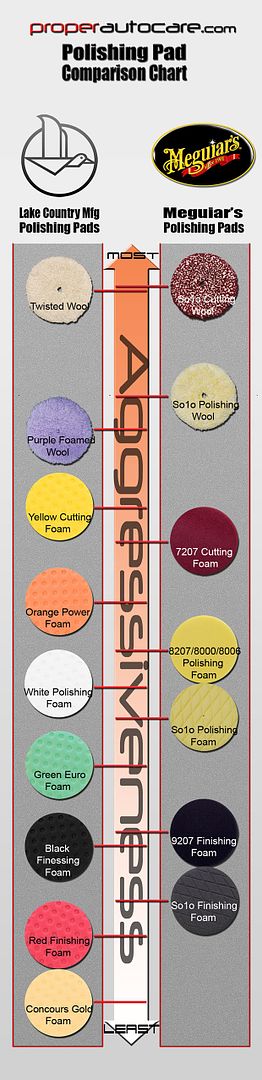

This chart is for general comparison use in terms of how the foam or wool material of the pad should perform against each other.

Keep in mind that there are many variables when selecting a foam pad.

Pad Diameter: The diameter of the pad controls the total contract surface of the area as well as what speed the pad moves across the paint in a given movement. On a rotary polisher a larger pad will act more aggressive because the outer edge of the pad is moving at a faster rate. On an orbital polisher a larger diameter pad will act less aggressive because of the increased deflection in the pad as well as the increase in friction and mass.

Pad Face Design: In general, flat pads, such as our Hi-Gloss Classic Flat style or Meguiar's SoftBuff 2.0 have the largest contact area against the paint. This makes flat pads more aggressive in polishing action when applied with rotary polisher but may cause random orbital polishers to bog, reducing cut. The increase in surface friction will also increase the amount of defection in the pad.

Pad's that have dimples, pockets, a convoluted 'waffle' patter, or are cross cut will be less aggressive on a rotary polisher and more aggressive on a dual-action polisher for the same reasons.

Let's make all of the cars shiny!

Comment

-

Re: pad selection driving me crazy!!!

Todd. Thanks for posting the chart. Makes things much clearer.

Comment

-

Re: pad selection driving me crazy!!!

Thanks for all the great info. No longer really confused about pad selection. As I have always detailed by hand, I never imagined how much there really was to the machine aspect. Again thanks not only for the quick replies, but easy to understand info.There's no reason to become alarmed, and we hope you'll enjoy the rest of your flight. By the way, is there anyone on board who knows how to fly a plane?

Comment

Comment