Re: Paint Thickness Gauge, Cheapo Harbor Freight First Test Results.

Just managed to calibrate and test the gauge just now after received it almost a week

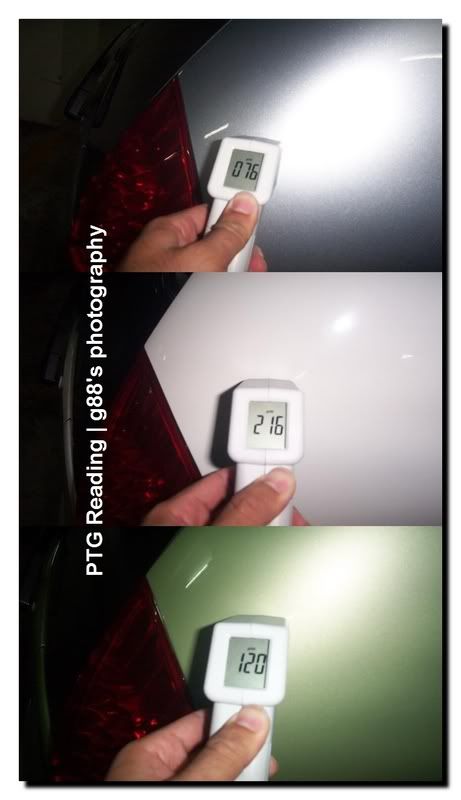

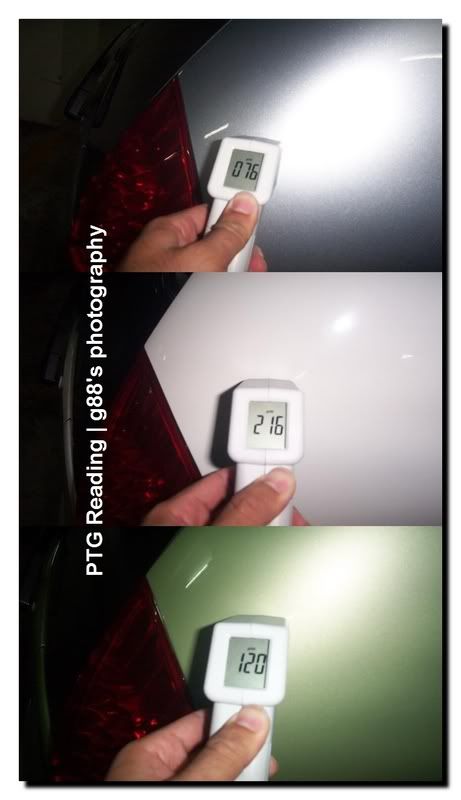

Here's the result i got..

Went to car park look for some car (from the resident of the condo) to get some reading...all car not wash in general...dunno even whether send for detail before or not..(except the green one)

The green one is from my g/f's car ...

...

Test on hood

I was told this is how the way of finding out the clear coat thickness..

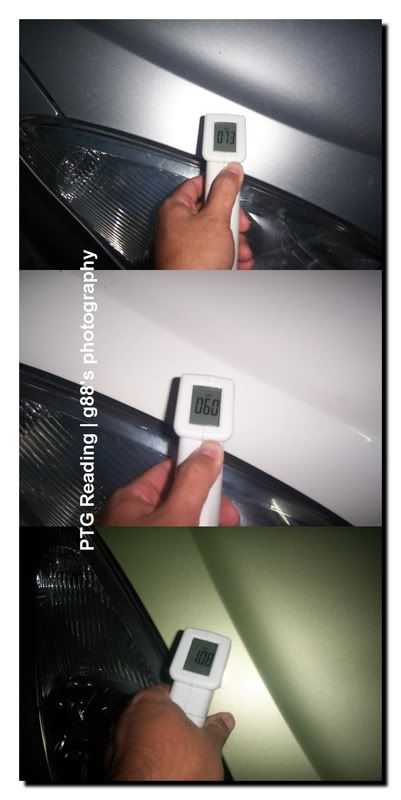

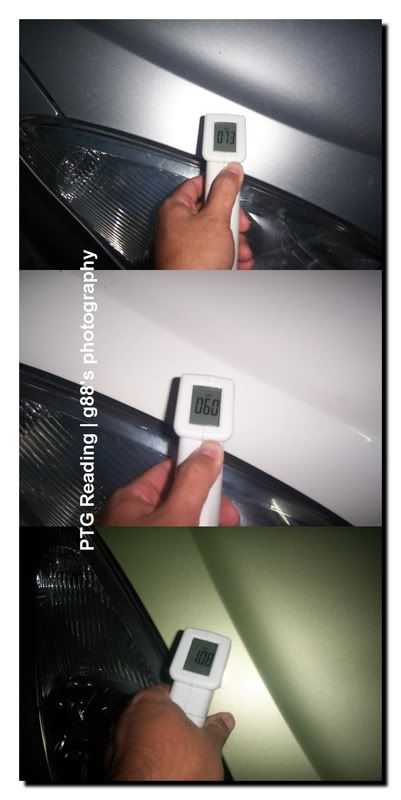

This is drive's door lower portion.

1st , measure the inner part of the door where usually no clear coat

2nd, measure the outer part of the door where finishing with clear coat

Than No.2 minus No.1 that would be the approx. thickness of clear coat..

Is there anything else i need to know ?

Actually MY Million QUESTION IS WHAT IS THE AVERAGE THICKNESS FOR A CLEAR COAT ? How many Mils or Micron ??

The label in my box said Standard Thickness is 4.0+ Mils or 101+ Micron

I won't do wet sanding....instead would wanna try more aggressive polisher like M86

Just managed to calibrate and test the gauge just now after received it almost a week

Here's the result i got..

Went to car park look for some car (from the resident of the condo) to get some reading...all car not wash in general...dunno even whether send for detail before or not..(except the green one)

The green one is from my g/f's car

...

...

Test on hood

I was told this is how the way of finding out the clear coat thickness..

This is drive's door lower portion.

1st , measure the inner part of the door where usually no clear coat

2nd, measure the outer part of the door where finishing with clear coat

Than No.2 minus No.1 that would be the approx. thickness of clear coat..

Is there anything else i need to know ?

Actually MY Million QUESTION IS WHAT IS THE AVERAGE THICKNESS FOR A CLEAR COAT ? How many Mils or Micron ??

The label in my box said Standard Thickness is 4.0+ Mils or 101+ Micron

I won't do wet sanding....instead would wanna try more aggressive polisher like M86

Comment